We’re doing things differently with timber panels.

Frank House precision-made timber panels are designed for residential and commercial building projects, and manufactured right here in New Zealand.

We work closely with builders, architects, developers, and customers to make sure every project is finished to the highest standard, and in the fastest time possible. We deliver your timber panels on-site, pre-assembled and ready to install.

The installation process is lightning fast, and houses can go from slab to weather-tight in as little as a week. The team at Frank House are also able to install the panels for you, because it’s all about working together to build a better New Zealand.

– INFORMATION FOR ARCHITECTS

At Frank House we combine the latest technology, and 30 years of experience building houses, to produce precision-made timber cassettes to exact standards with the following features:

- Proudly made with Nelson Pine LVL framing 90 – 190mm.

- No dwangs.

- IBS RAP Board.

- Cavity batten installed.

- Window seals installed.

- Hold downs in place ready to be fitted to floor structure.

- Double top plate.

- Floor panels to your job specific design.

- Window measure supplied to your manufacturer eliminating waiting times.

- We also deal with your truss detailer.

– FRANK PRODUCTS

External Panels

Internal Walls

Floor Casettes

Roofing Panels

– FACTORY CONTROLLED PRODUCTION

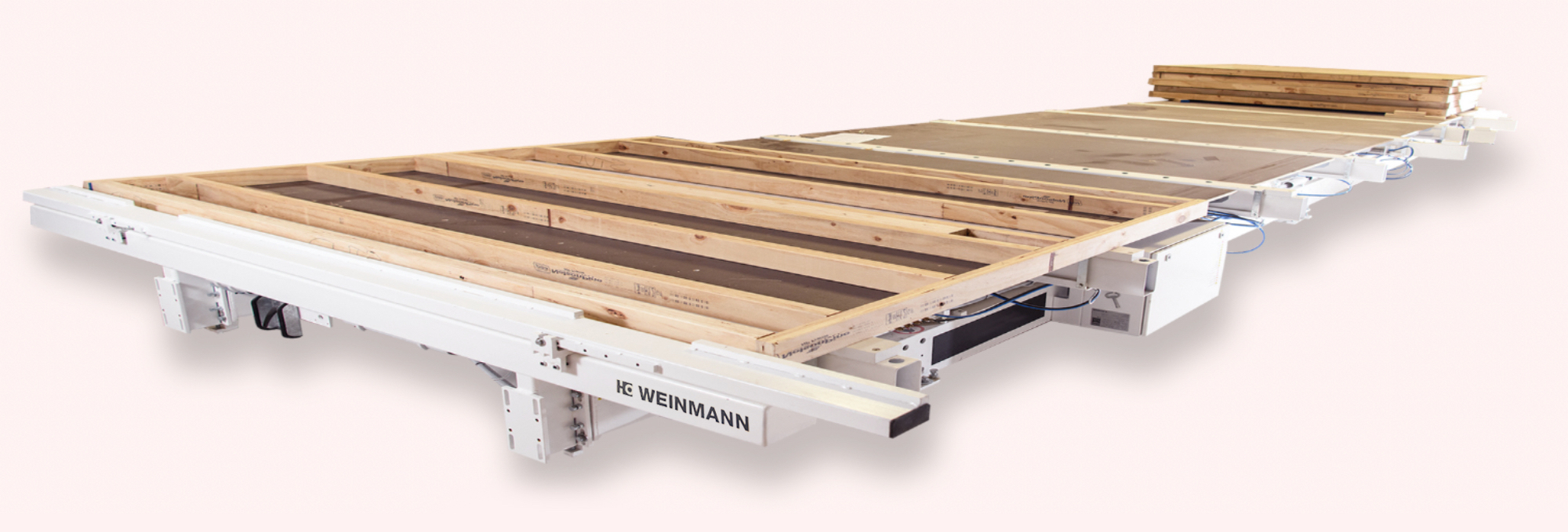

Our Factory is based in Waikanae. It houses our state-of-art German Weinmann Homag machinery.

This is where we are re-thinking the construction process from our factory floor. It’s here that we make our pre-manufactured timber wall, floor, and roof components – using Kiwi-made materials – and then deliver them directly to building sites.

– OUR PROCESS

Pre-construction

First we’ll meet with you to go over your project’s specific requirements.

Design & Engineering

We’ll input your architectural plans and technical information into our advanced software and provide you with a detailed quote for the production of your panels.

Off-site Manufacturing

All the components for your build will be manufactured by our state-of-the-art machinery, in our factory-controlled environment.

Delivery

Your precision-made panels will be delivered straight from our factory to your site, on a previously agreed date that works with your build schedule.

On-site Assembly

Once on-site the panels are easily assembled by your team or ours.